The nail manufacturing industry has undergone a significant transformation over the past few decades, evolving from traditional handcrafting methods to sophisticated, automated production processes. This evolution has been driven by the increasing demand for high-quality, durable, and aesthetically pleasing nails that cater to a diverse range of applications, from construction to decorative purposes. Advanced nail manufacturing encompasses a variety of techniques and technologies that enhance the efficiency, precision, and quality of nail production.

As the industry continues to innovate, manufacturers are exploring new materials, designs, and production methods that not only meet market demands but also push the boundaries of what is possible in nail design and functionality. In this context, advanced nail manufacturing is not merely about producing nails; it is about creating solutions that address the specific needs of various industries. For instance, the construction sector requires nails that can withstand extreme conditions, while the fashion industry seeks unique designs that can elevate aesthetic appeal.

The integration of advanced technologies such as automation, robotics, and 3D printing has revolutionized the way nails are produced, allowing for greater customization and efficiency. As we delve deeper into the intricacies of advanced nail manufacturing, it becomes evident that this sector is at the forefront of innovation, setting new standards for quality and performance.

Key Takeaways

- Automation significantly enhances efficiency and precision in nail production.

- Advanced technologies enable higher quality and faster manufacturing processes.

- 3D printing introduces new possibilities for customized and complex nail designs.

- Sustainable practices are increasingly integrated to improve environmental impact.

- The industry faces challenges but also opportunities for innovation and growth.

The Role of Automation in Nail Production

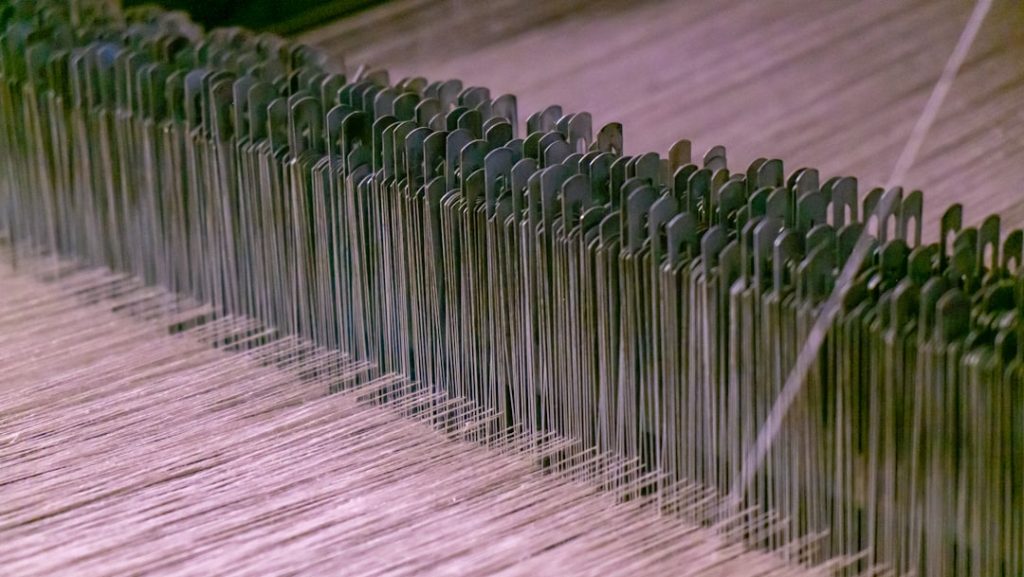

Automation has become a cornerstone of modern nail production, significantly enhancing the speed and accuracy of manufacturing processes. Automated systems are capable of performing repetitive tasks with minimal human intervention, which not only reduces labor costs but also minimizes the risk of errors associated with manual handling. For example, automated machines can efficiently feed raw materials into production lines, shape and cut nails to precise specifications, and package finished products for distribution—all within a fraction of the time it would take human workers.

This level of efficiency is crucial in meeting the growing demand for nails in various industries, particularly in construction where timely delivery can impact project timelines. Moreover, automation allows for greater consistency in product quality. Traditional methods often result in variations in nail size, shape, and finish due to human error or inconsistencies in raw materials.

In contrast, automated systems utilize advanced sensors and control mechanisms to ensure that each nail produced meets stringent quality standards. This consistency is vital for applications where structural integrity is paramount, such as in building construction. Additionally, automation facilitates real-time monitoring of production processes, enabling manufacturers to quickly identify and rectify any issues that may arise during production.

As a result, the integration of automation not only streamlines operations but also enhances overall product reliability.

Advancements in Nail Manufacturing Technology

The landscape of nail manufacturing technology has seen remarkable advancements that have transformed traditional practices into cutting-edge processes. One notable development is the introduction of high-speed stamping machines that can produce thousands of nails per hour with exceptional precision. These machines utilize advanced die technology to create nails in various shapes and sizes, catering to specific industry requirements.

For instance, roofing nails require different specifications compared to finishing nails, and modern stamping machines can easily accommodate these variations without compromising on quality or speed. Another significant advancement is the use of computer numerical control (CNC) technology in nail production. CNC machines allow for intricate designs and customizations that were previously unattainable with conventional methods.

By programming specific parameters into the CNC system, manufacturers can produce nails with unique features such as specialized coatings or complex geometries that enhance performance. This level of customization is particularly beneficial for niche markets where standard products may not suffice. Furthermore, advancements in material science have led to the development of new alloys and coatings that improve the durability and corrosion resistance of nails, ensuring they perform optimally in various environments.

Benefits of Advanced Nail Manufacturing Machines

| Benefit | Description | Metric/Impact |

|---|---|---|

| Increased Production Speed | Advanced machines can produce nails at a much faster rate compared to manual or older machines. | Up to 10,000 nails per minute |

| Improved Nail Quality | Consistent shaping and sizing reduce defects and improve product reliability. | Less than 1% defect rate |

| Reduced Labor Costs | Automation reduces the need for manual labor, lowering operational expenses. | Labor cost reduction by 40% |

| Energy Efficiency | Modern machines consume less power, contributing to lower energy bills and environmental impact. | Energy consumption reduced by 25% |

| Versatility | Ability to manufacture various types and sizes of nails with minimal adjustments. | Supports 10+ nail types and sizes |

| Reduced Material Waste | Precision manufacturing minimizes scrap and optimizes raw material usage. | Material waste reduced by 15% |

| Enhanced Safety | Automated systems reduce human exposure to hazardous processes. | Workplace accidents reduced by 30% |

The benefits of advanced nail manufacturing machines extend beyond mere efficiency; they encompass a wide range of advantages that contribute to overall business success. One primary benefit is the reduction in production costs. By automating processes and utilizing high-speed machinery, manufacturers can significantly lower labor costs while increasing output.

This cost-effectiveness allows companies to remain competitive in a market where price sensitivity is prevalent. Additionally, advanced machines often require less maintenance than older models, further reducing operational expenses. Another key advantage is the ability to scale production quickly in response to market demands.

Advanced manufacturing machines can be easily reconfigured or programmed to produce different types or sizes of nails without extensive downtime. This flexibility is crucial in an industry characterized by fluctuating demand patterns. For example, during peak construction seasons, manufacturers can ramp up production to meet increased orders without sacrificing quality or delivery timelines.

Furthermore, advanced machines often come equipped with data analytics capabilities that provide insights into production efficiency and quality control metrics. This data-driven approach enables manufacturers to make informed decisions that enhance productivity and reduce waste.

The Impact of 3D Printing on Nail Production

3D printing technology has emerged as a game-changer in various manufacturing sectors, including nail production. This innovative approach allows for the creation of complex geometries and customized designs that traditional manufacturing methods cannot achieve. In nail production, 3D printing enables manufacturers to produce prototypes quickly and cost-effectively, facilitating rapid design iterations and testing before committing to full-scale production.

This capability is particularly valuable for companies looking to introduce new products or respond to specific customer requests. Moreover, 3D printing opens up possibilities for creating nails with unique features tailored to specific applications. For instance, nails designed for specialized construction projects may require unique shapes or materials that enhance their performance under specific conditions.

With 3D printing, manufacturers can experiment with different materials—such as biodegradable plastics or advanced composites—that may offer superior performance characteristics compared to traditional metal nails. This level of customization not only meets market demands but also fosters innovation within the industry.

Sustainability and Efficiency in Nail Manufacturing

As environmental concerns continue to rise globally, sustainability has become a critical focus within the nail manufacturing industry. Advanced manufacturing techniques are increasingly being designed with sustainability in mind, aiming to minimize waste and reduce energy consumption throughout the production process. For example, manufacturers are adopting lean manufacturing principles that emphasize efficiency and waste reduction at every stage—from raw material sourcing to final product delivery.

Additionally, many companies are exploring eco-friendly materials for nail production. Traditional metal nails often rely on non-renewable resources; however, advancements in material science have led to the development of sustainable alternatives such as recycled metals or biodegradable composites. These materials not only reduce environmental impact but also appeal to a growing consumer base that prioritizes sustainability in their purchasing decisions.

Furthermore, energy-efficient machinery and renewable energy sources are being integrated into manufacturing facilities to further decrease carbon footprints.

The Future of Customized Nail Designs

The future of nail manufacturing is poised for a significant shift towards customization and personalization. As consumer preferences evolve towards unique and individualized products, manufacturers are increasingly investing in technologies that enable bespoke nail designs tailored to specific customer needs. This trend is particularly evident in sectors such as fashion and interior design, where distinctive aesthetics play a crucial role in product appeal.

Advanced technologies such as digital printing and laser engraving are paving the way for intricate designs that were once considered impractical or too costly to produce at scale. For instance, manufacturers can now create nails adorned with intricate patterns or logos that reflect brand identity or personal style. This level of customization not only enhances product appeal but also fosters customer loyalty as consumers seek out products that resonate with their individual tastes.

Challenges and Opportunities in the Nail Manufacturing Industry

While the advancements in nail manufacturing present numerous opportunities for growth and innovation, they also come with their own set of challenges. One significant challenge is the need for continuous investment in technology and training to keep pace with rapid advancements in manufacturing processes. Companies must remain agile and willing to adapt to new technologies while ensuring their workforce is equipped with the necessary skills to operate advanced machinery effectively.

Additionally, competition within the industry is intensifying as new players enter the market with innovative solutions and products. Established manufacturers must differentiate themselves through quality, customer service, and unique offerings to maintain their market position. However, this competitive landscape also presents opportunities for collaboration between manufacturers and technology providers to develop cutting-edge solutions that address emerging market needs.

In conclusion, while challenges exist within the nail manufacturing industry, the potential for growth through innovation and sustainability remains robust. As manufacturers continue to embrace advanced technologies and prioritize customization, they will be well-positioned to meet evolving consumer demands while contributing positively to environmental sustainability efforts.