Vacuum sealing is a preservation method that has gained significant traction in both home kitchens and commercial food establishments. The primary advantage of vacuum sealing lies in its ability to extend the shelf life of food products by removing air from the packaging. This process inhibits the growth of aerobic bacteria and mold, which thrive in oxygen-rich environments.

By creating a vacuum-sealed environment, food can remain fresh for much longer periods compared to traditional storage methods. For instance, vacuum-sealed meats can last up to three to five times longer than those stored in standard packaging, making it an invaluable technique for both reducing food waste and saving money. In addition to prolonging freshness, vacuum sealing also helps in preserving the flavor, texture, and nutritional value of food.

When food is vacuum sealed, it retains its moisture and prevents freezer burn, which can occur when food is exposed to air in the freezer. This is particularly beneficial for items like fruits and vegetables, which can lose their crispness and taste when improperly stored. Furthermore, vacuum sealing can enhance marination processes; by removing air, the marinade can penetrate deeper into the food, resulting in more flavorful dishes.

The versatility of vacuum sealing extends beyond just preservation; it also facilitates meal prep and portion control, allowing individuals to prepare meals in advance and store them conveniently.

Key Takeaways

- Vacuum sealing preserves food freshness and extends shelf life by removing air and preventing spoilage.

- Selecting the appropriate commercial vacuum sealer depends on your specific food types and volume needs.

- Proper food preparation, such as drying and portioning, is essential for effective vacuum sealing.

- Vacuum sealing is ideal for sous vide cooking, ensuring even cooking and flavor retention.

- Regular maintenance and cleaning of vacuum sealers prevent malfunctions and prolong machine lifespan.

Choosing the Right Commercial Vacuum Sealer Machine

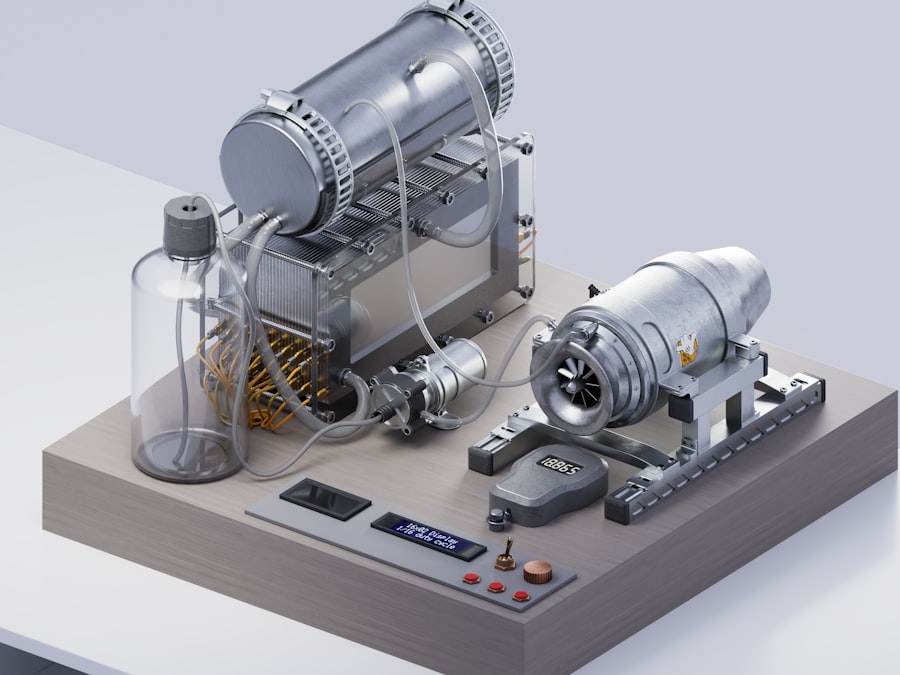

Selecting the appropriate commercial vacuum sealer machine is crucial for businesses that rely on food preservation. There are several factors to consider when making this decision, including the type of food being sealed, the volume of production, and the specific features required for optimal performance. Commercial vacuum sealers come in various styles, such as chamber sealers and external sealers.

Chamber sealers are typically more efficient for high-volume operations as they can handle larger quantities of food at once and are designed to create a complete vacuum within a sealed chamber. This type of machine is ideal for businesses that require consistent results and need to seal liquids or moist foods without the risk of spillage. On the other hand, external sealers are more compact and portable, making them suitable for smaller operations or those with limited space.

They work by placing the bag into the machine and sealing it from the outside. While they may not be as efficient for large quantities, they are often more affordable and easier to use for occasional sealing tasks. Additionally, when choosing a commercial vacuum sealer, it’s essential to consider features such as adjustable sealing time, temperature control, and compatibility with different bag types.

Machines with built-in marinating functions or those that offer multi-function capabilities can also provide added value for businesses looking to diversify their food preparation processes.

Properly Preparing Food for Vacuum Sealing

Before vacuum sealing food, proper preparation is essential to ensure optimal results. The first step involves cleaning and trimming the food items to remove any excess fat, skin, or unwanted parts that could affect the sealing process or lead to spoilage. For instance, when sealing meats, trimming away excess fat can help prevent rancidity during storage.

Additionally, washing fruits and vegetables thoroughly is crucial to eliminate any dirt or pesticides that may be present on their surfaces. Once cleaned, it’s advisable to dry the items completely; moisture can interfere with the vacuum sealing process and lead to compromised seals. Another important aspect of preparation is portioning food into appropriate sizes before sealing.

This not only makes it easier to thaw and use later but also helps in managing inventory effectively. For example, when sealing bulk items like cheese or deli meats, cutting them into smaller portions allows for quicker access without needing to open an entire package. For liquids or moist foods, it’s beneficial to freeze them briefly before vacuum sealing; this prevents liquid from being sucked into the machine during the sealing process.

By taking these preparatory steps seriously, one can significantly enhance the effectiveness of vacuum sealing and ensure that food remains fresh and flavorful.

Vacuum Sealing Best Practices for Maximum Freshness

| Best Practice | Description | Recommended Metric | Impact on Freshness |

|---|---|---|---|

| Use High-Quality Vacuum Bags | Bags designed specifically for vacuum sealing prevent air and moisture ingress. | Material Thickness: 3-4 mils | Extends freshness by up to 50% |

| Remove as Much Air as Possible | Ensures minimal oxygen exposure to slow down spoilage. | Vacuum Pressure: 20-25 inHg (inches of mercury) | Reduces oxidation and freezer burn |

| Seal Immediately After Vacuuming | Prevents air from re-entering the bag before sealing. | Seal Time: 2-3 seconds | Maintains vacuum integrity |

| Pre-Freeze Moist or Delicate Foods | Prevents crushing and preserves texture during sealing. | Freeze Time: 1-2 hours before sealing | Improves texture retention |

| Label and Date Packages | Keeps track of storage time to ensure timely use. | Label with Date and Contents | Reduces risk of spoilage from forgotten items |

| Store Vacuum-Sealed Items Properly | Keep sealed packages in appropriate temperature conditions. | Refrigeration: 34-40°F (1-4°C), Freezing: 0°F (-18°C) | Maximizes shelf life |

To achieve maximum freshness through vacuum sealing, adhering to best practices is essential. One key practice is ensuring that bags are properly sized for the items being sealed. Using bags that are too large can lead to excess air remaining in the package, while bags that are too small may not allow for a proper seal.

It’s advisable to leave enough space at the top of the bag—typically around three inches—to allow for a secure seal without compromising the integrity of the package. Additionally, using high-quality vacuum-seal bags designed specifically for this purpose can make a significant difference in preserving food quality. Another best practice involves labeling sealed bags with dates and contents before storage.

This simple step helps in tracking freshness and ensures that older items are used first, reducing waste. It’s also important to store vacuum-sealed items properly; while vacuum sealing extends shelf life, improper storage conditions can still lead to spoilage. For instance, vacuum-sealed items should be kept in a cool, dark place or refrigerated/frozen as appropriate.

When freezing vacuum-sealed foods, placing them flat in the freezer allows for quicker freezing and easier stacking later on. By following these best practices, individuals and businesses can maximize the benefits of vacuum sealing and maintain high-quality food products.

Extending Shelf Life with Vacuum Sealing

The ability of vacuum sealing to extend shelf life is one of its most compelling advantages. By removing air from packaging, vacuum sealing significantly slows down oxidation processes that lead to spoilage. For example, fruits like strawberries or blueberries can last up to two weeks longer when vacuum sealed compared to being stored in traditional containers.

Similarly, vacuum-sealed vegetables retain their crispness and nutritional value much longer than those stored in open bags or containers. This extended shelf life not only benefits consumers by reducing waste but also provides businesses with a competitive edge by allowing them to offer fresher products over longer periods. In addition to fruits and vegetables, vacuum sealing is particularly effective for proteins such as fish and meat.

When properly sealed and stored at appropriate temperatures, vacuum-sealed meats can last several years in the freezer without losing quality or flavor. This is especially advantageous for restaurants or catering services that need to manage inventory efficiently while ensuring that their offerings remain fresh and appealing. Moreover, vacuum sealing can also be applied to dry goods like grains and nuts; by eliminating air exposure, these items can be protected from rancidity and pest infestations, further extending their shelf life.

Using Vacuum Sealing for Sous Vide Cooking

Sous vide cooking has gained popularity among culinary enthusiasts and professionals alike due to its precision and ability to enhance flavors while maintaining texture. Vacuum sealing plays a pivotal role in this cooking method by ensuring that food is cooked evenly and retains its moisture during the sous vide process. When food is vacuum sealed in a bag before being submerged in a water bath at controlled temperatures, it cooks uniformly without overcooking or drying out.

This technique allows chefs to achieve perfect doneness consistently across various types of proteins. Moreover, vacuum sealing prior to sous vide cooking allows for enhanced flavor infusion through marinades or seasonings. As the food cooks in its sealed environment, flavors penetrate more deeply than they would through traditional cooking methods.

For instance, marinating chicken breasts before sous vide cooking results in a more flavorful dish compared to marinating after cooking. Additionally, sous vide cooking eliminates the need for added fats or oils typically used in other cooking methods since the sealed environment retains natural juices. This not only promotes healthier cooking but also simplifies cleanup afterward.

Maintaining and Cleaning Your Commercial Vacuum Sealer Machine

Proper maintenance and cleaning of commercial vacuum sealer machines are vital for ensuring longevity and optimal performance. Regularly inspecting seals and gaskets is essential; worn-out seals can lead to air leaks that compromise the effectiveness of vacuum sealing. Cleaning these components after each use helps prevent residue buildup that could affect performance over time.

Most machines come with user manuals that provide specific instructions on how to clean various parts effectively without damaging them. In addition to routine cleaning, it’s important to perform periodic deep cleaning of the machine itself. This includes wiping down surfaces with mild detergents and sanitizing components that come into contact with food.

For machines equipped with filters or oil reservoirs (in oil-pump models), these should be checked regularly and replaced as needed according to manufacturer guidelines. Keeping a maintenance log can also be beneficial; documenting cleaning schedules and any repairs made ensures that machines are kept in peak condition while providing insights into usage patterns that may inform future purchasing decisions.

Troubleshooting Common Issues with Commercial Vacuum Sealer Machines

Despite their efficiency, commercial vacuum sealer machines may encounter issues from time to time that require troubleshooting. One common problem is failure to create a proper seal; this could be due to several factors such as improper bag placement or moisture on the sealing surface. Ensuring that bags are correctly positioned within the machine and checking for any moisture before sealing can often resolve this issue quickly.

If problems persist, inspecting seals for wear or damage may be necessary. Another frequent issue involves air leaks after sealing has occurred; this can lead to spoilage if not addressed promptly. Air leaks may result from using incompatible bags or incorrect settings on the machine itself.

It’s advisable to use high-quality bags specifically designed for vacuum sealing and ensure that settings match the type of food being sealed—moist foods may require different settings than dry items. If air leaks continue despite using appropriate materials and settings, consulting the manufacturer’s troubleshooting guide or seeking professional repair services may be necessary to restore functionality effectively. By understanding these aspects of vacuum sealing—from its benefits and best practices to maintenance and troubleshooting—individuals and businesses alike can harness its full potential for preserving food quality while enhancing culinary experiences.